How Mountable Massage Devices Work: A Practical Guide

Outline

– Introduction: Why mountable massage devices exist, who benefits, and the trade-offs compared with handheld tools.

– Inside the machine: motors, gear trains, cams, sensors, and control logic that shape amplitude, frequency, and force.

– Mounting and ergonomics: brackets, clamps, isolation, angles, reach, and how setup influences comfort and noise.

– Massage modalities and physiology: percussive vs. vibrational vs. kneading; what the body feels and why safety matters.

– Practical setup, care, and purchasing signals; final checklist and conclusion tailored to home users, athletes, and busy professionals.

Introduction: Why Mountable Massage Devices Matter

Mountable massage devices promise something handheld tools can’t easily deliver: consistent, hands-free pressure at repeatable angles and heights. Picture finishing a workout or a long shift at a desk and being able to lean your calves, back, or shoulders into a steady rhythm without juggling a grip or asking for help. The concept is simple—anchor the massaging mechanism to a rigid surface, then bring your body to it. The execution, however, blends engineering with ergonomics, because a device that hums gently in the showroom can rattle, resonate, or feel awkward if placed poorly in a real room.

Why do these products matter? First, they broaden access. Users with limited hand strength or range of motion can still apply targeted pressure. Second, they can improve repeatability. Once a device is set at a precise height and angle, you can return to that exact setup tomorrow, making it easier to track routines and results. Third, they can be more shareable. In a gym corner or a small clinic, a fixed device becomes a station, much like a foam-rolling area, reducing downtime between users.

They also come with trade-offs worth understanding before you buy or install. A mount transmits force into walls, doors, or racks, so stability and noise become shared problems for the structure and the device. Placement defines comfort: too high, and necks strain; too low, and hips twist. And contrary to the myth that bigger motors always mean deeper relief, poorly tuned amplitude or frequency can make a device feel buzzy instead of satisfying. Ultimately, seeing how these units actually work—what moves, what flexes, what heats up—helps you pick a model, mount it with confidence, and use it safely and effectively. This guide opens the casing, so to speak, and turns the technical into the practical.

– Who benefits most: home gym owners, endurance athletes, strength trainees, desk workers with tight hip flexors, and caregivers seeking predictable setups.

– What to expect: easier targeting of large muscle groups, reduced grip fatigue, and more consistent session timing.

– What to watch: structural stability, decibel levels in shared spaces, and control over amplitude, frequency, and pressure.

Inside the Machine: Motors, Mechanisms, and Control

At the heart of many mountable massage devices is a compact electric motor coupled to a mechanism that converts rotational motion into rhythmic movement. The most common architectures include: percussive drives using an eccentric cam or crank to produce a linear stroke; vibrational drives using unbalanced rotors that generate high-frequency tremors; and kneading or rolling drives with rotating nodes for circular motion. Each path has trade-offs. A percussive cam with a 10–16 mm stroke at roughly 20–40 cycles per second can feel decisively “punchy,” reaching into thicker muscle groups. A vibrational system running 50–80 cycles per second with a small amplitude feels lighter and more diffuse, suitable for warm-ups, sensitive areas, or post-session cooldowns.

Motors matter, but so does gearing. A brushless DC motor paired with a reduction gearbox provides torque at manageable temperatures. Without adequate gearing, the motor can stall when users lean in hard; with too much reduction, it may feel sluggish at higher speeds. Engineers also manage heat and durability through bearings, bushings, and balanced rotating parts. A slightly heavier flywheel can smooth motion, but if mass isn’t balanced, you get rattle and early wear. Rubber bumpers and polymer guides reduce chatter as the cam reverses direction thousands of times per session.

Electronics bring finesse. Pulse-width modulation regulates speed smoothly, while current sensing offers a proxy for force: as you push, the controller detects rising load and can either hold speed, allow a dip, or cap output to protect the motor. Thermal sensors monitor coil and driver temperatures, throttling power if things get warm. Some units add closed-loop control so set speeds stay steady even as pressure changes. Others keep it simple with stepped modes, which is fine if you value predictable presets over infinite adjustability.

Noise and feel are two sides of the same coin. Most sound comes from three places: the motor’s electromagnetic whine, air movement from fans or rotating parts, and structural vibration that escapes into mounts and walls. The last one is the biggie in fixed installations. Dense housings, elastomer isolation, and stiffer brackets funnel energy into your muscles rather than the room. A practical takeaway: a well-isolated mount often sounds quieter than a louder motor on a flimsy bracket. When comparing options, listen for tonal quality (low thrum versus high buzz) and watch for visible flex in arms and plates, which hints at energy lost to wobble rather than therapy.

– Key specs decoded: stroke length (reach of each hit), frequency (hits per second), stall force (how hard you can lean), duty cycle (how long it can run without overheating).

– Design tells: balanced rotating parts, metal gear trains, and replaceable wear components extend lifespan.

– Control perks: closed-loop speed control keeps rhythm consistent under pressure, improving feel and predictability.

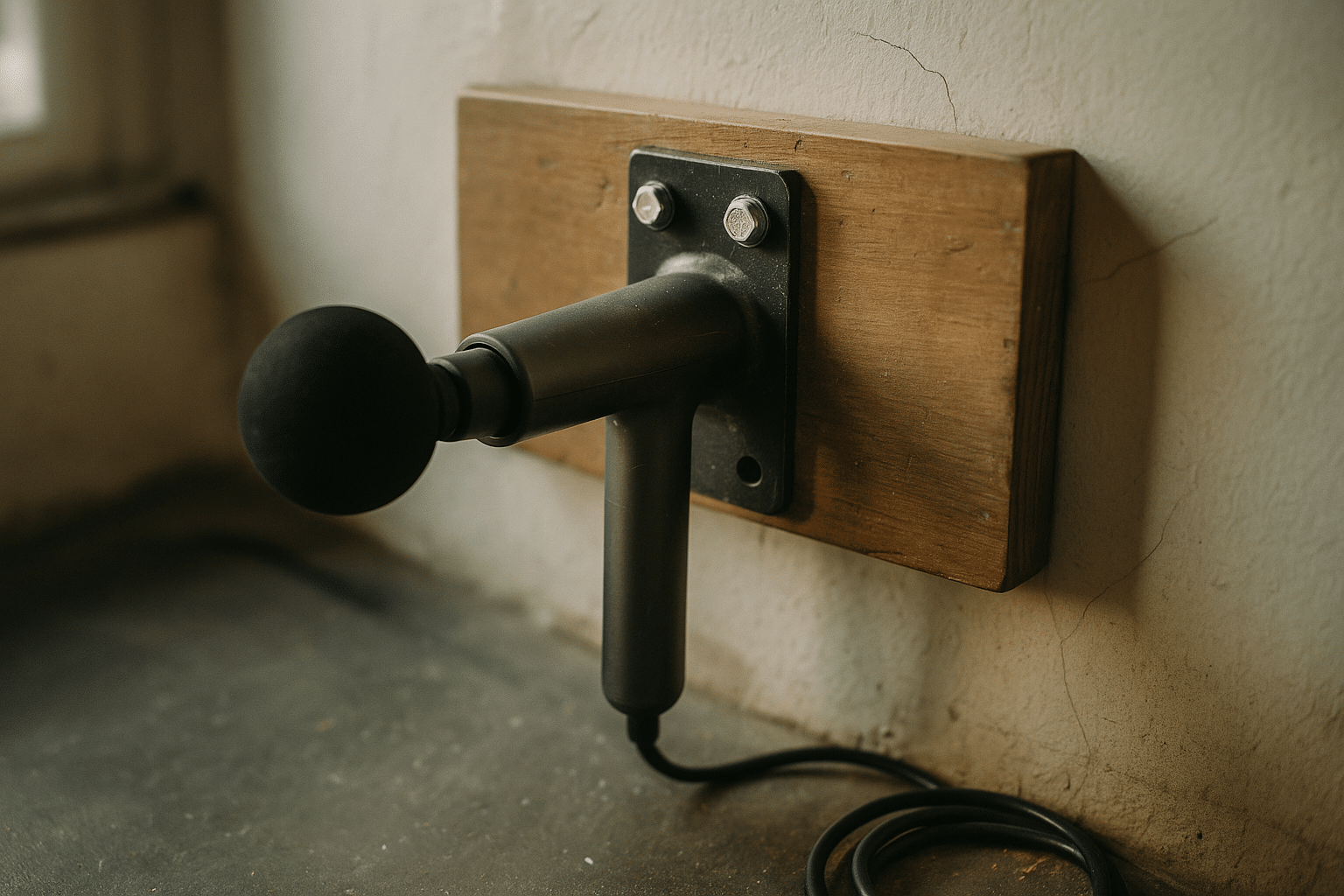

From Desk to Doorframe: Mounting Systems, Stability, and Ergonomics

Mounting is where promising hardware either shines or shakes apart. Common systems include wall plates, rack clamps, doorframe braces, suction or adhesive pads for smooth surfaces, and freestanding stands with weighted bases. Wall plates and rack clamps tend to be the most stable because they tie into rigid, load-bearing structures. Doorframe braces trade permanence for flexibility but demand careful placement to avoid marring wood or slipping during angled pressure. Suction or adhesive pads are quick but sensitive to surface prep, humidity, and dust, and they usually limit force before detachment risk grows.

Materials tell a story. Steel brackets resist deformation, which protects alignment at higher loads. Aluminum saves weight and resists corrosion, but thin sections can ring like a bell if not damped. Polymers reduce vibration transmission and are kinder to walls, yet they must be gusseted or fiber-reinforced to prevent creep over time. The quiet heroes are the isolation layers—rubber grommets, urethane washers, or viscoelastic pads that filter harsh peaks while letting useful motion pass. Done well, isolation makes the device feel plush and reduces the “my wall is humming” complaint.

Ergonomics transform raw motion into comfort. Height is the first dial: mid-back targets around the shoulder blade region often align near the bottom of the sternum height on an average adult; calves want something closer to knee height; glutes and hamstrings typically feel right around hip level. Angle is the second: a 10–20 degree upward tilt lets you lean without overextending wrists or arching your low back. Reach is the third: arms or sliders that move the head a few inches left or right help find trigger points without twisting your torso.

Stability and safety go hand in hand. A bracket that bends a few millimeters under load may seem harmless, but it changes how the stroke lands and amplifies noise. Over time, hardware can loosen. Periodic checks—tightening bolts, inspecting anchors, and cleaning debris under isolation pads—keep things true. In apartments, consider a clamp-on solution to a sturdy rack or a freestanding stand with a weighted base to spare walls. In a garage gym, lag bolts into studs or a steel rack give headroom for higher force settings. If you ever see cracked plaster, out-of-square mounts, or creeping adhesive edges, pause and remediate before the next session.

– Mount options at a glance: wall plate (permanent, rigid), rack clamp (adjustable, strong), door brace (portable, moderate force), suction/adhesive (quick, light force), freestanding base (no drilling, needs mass).

– Ergonomic dials: height, angle, reach, and stance control comfort and targeting.

– Maintenance habit: monthly torque check on bolts and a quick wipe of pads and brackets to retain grip and hush squeaks.

Massage Modalities, Physics, and What Your Body Feels

Different drive styles create distinct sensations, and understanding them helps you pick a setup and session plan that suits your goals. Percussive motion delivers discrete, deeper-feeling hits shaped by amplitude and frequency. Larger amplitudes (for example, 12–16 mm) at moderate frequencies (around 20–35 cycles per second) can feel decisive on glutes, hamstrings, and quads, especially when you can lean in hands-free. Vibrational motion, with small amplitude at higher frequency (often 50–80 cycles per second), spreads sensation more evenly, which many people prefer for warm-up, sensitive regions, or longer, low-intensity sessions. Kneading or rolling uses rotating nodes to mimic circular thumb pressure, useful along paraspinal muscles when movement is kept parallel to the spine.

Physics gives a few anchors. Force at contact is a product of the device’s output and your lean-in pressure. Leaning adds preload, which can increase effective depth up to the point where stall force or comfort limits are reached. Damping—your tissue’s resistance to motion—filters high frequencies, which is why a high-speed vibrational unit can feel “surface level” compared to a slower, longer stroke even if both motors draw similar power. Isolation in the mount also changes the feel: a slightly softer interface can round off harsh peaks, turning a sharp knock into a satisfying thud.

What about the body’s response? Light, rhythmic pressure can stimulate mechanoreceptors, promoting a sense of relaxation and temporary relief from stiffness. Some users report improved warm-up readiness when using low-to-moderate intensity for a few minutes before activity. Post-activity, moderate pressure may support the perception of recovery by easing muscle tension. None of this replaces medical care, and anyone with injuries, circulatory issues, or implanted devices should consult a qualified professional before using powered massagers.

Session structure matters more than chasing maximum numbers. A practical template is to start with low frequency and pressure to “map” tender spots, then increase one variable at a time. Two to four minutes per large muscle group is a common, sustainable range, with brief check-ins for numbness, tingling, or sharp pain—signs to stop. Avoid bony landmarks, varicose veins, and fresh bruises. On the back, keep movements parallel to the spine rather than directly over spinous processes. If a device offers multiple heads, choose shapes that match the area: broad pads for quads and calves, softer domes for forearms, and narrower tips only for controlled, light touch around denser tissue.

– Modality quick picks: percussive for dense muscles, vibrational for gentle warm-ups, kneading for slow, positional work.

– Sensation tuning: adjust amplitude first for depth, frequency for feel, and pressure for intensity.

– Safety anchors: steer clear of joints and bones, limit time per spot, and respect any medical guidance specific to your situation.

Conclusion and Actionable Checklist: Setups That Work in Real Rooms

By now, the picture should be clearer: a mountable massage device is a small machine that converts spinning motion into a pattern you can lean into, and the mount is the stage that decides whether that pattern feels smooth or shaky. Choosing and installing wisely means balancing output specs with the realities of your space, your body, and your noise tolerance. For home users and athletes, the prize is convenience—repeatable angles, no grip fatigue, and a station that invites short, frequent sessions instead of once-in-a-while marathons. For busy professionals outfitting a small studio, it’s workflow: a reliable, quiet corner that multiple clients can use without constant adjustment.

Use this concise checklist to move from idea to satisfying routine:

– Define goals: warm-up, cooldown, or targeted tension relief. Different aims favor different amplitudes and frequencies.

– Match modality: percussive for depth; vibrational for gentle, longer sessions; kneading for slow, positional work.

– Read specs in context: stroke length (mm), frequency (cycles per second), stall behavior under load, and duty cycle for session length.

– Evaluate mounts: wall plate or rack clamp for rigidity; freestanding if drilling is off-limits. Look for isolation pads to tame noise.

– Plan ergonomics: mark heights for calves, glutes, mid-back, and shoulders; test a 10–20 degree tilt to reduce awkward angles.

– Manage sound: choose denser brackets, add rubber washers, and place on shared walls only if neighbors are tolerant.

– Maintain: wipe heads and brackets, check fasteners monthly, and keep vents clear for cooling.

When installing, locate solid structure—studs, masonry, or steel—and use anchors rated well above expected loads. Test at low speed first, listening for buzzes that hint at loose hardware or mismatched materials. Adjust height and angle with a simple routine: start low for calves, move to hip level for glutes and hamstrings, then mid-back and shoulders. Keep sessions short and consistent rather than infrequent and intense; over time, small habits outperform heroic bouts.

In short, let engineering guide your comfort. Pick a device whose mechanics match your aim, give it a mount that respects physics, and build a routine that respects your body. The result is a compact corner of your room that quietly earns its keep—ready whenever you need a steady rhythm to loosen the day’s knots, no scheduling required.