Used Trailers for Sale: A Practical Buyer’s Guide to Types, Inspection, and Pricing

Outline

– Choosing the right trailer for your tasks and tow vehicle

– Inspection checklist and common failure points

– Pricing, depreciation, and negotiation

– Where to shop and how to vet listings

– Ownership, safety, and final checklist

Choosing the Right Type and Size for Your Needs

Before browsing classifieds, define what you need the trailer to do and what your tow vehicle can safely pull. Two numbers matter most: the trailer’s Gross Vehicle Weight Rating (GVWR) and your vehicle’s rated towing capacity. The GVWR indicates the maximum allowable weight of the trailer plus cargo; your tow rating must exceed the actual loaded weight. It helps to sketch your most demanding use case—moving a compact tractor, transporting ATVs, hauling construction debris—and size around that scenario rather than today’s lightest task.

Common categories each serve a distinct purpose. An open utility trailer (single-axle, light-duty) is popular for lawn equipment, small furniture moves, and weekend projects. Enclosed cargo models shield tools and goods from weather and theft, adding height and aerodynamic drag but doubling as mobile storage. Flatbeds and car haulers offer wide, low decks for vehicles, pallets, and equipment. Dump trailers lift to unload gravel or brush, trading weight for hydraulic convenience. Equipment trailers with tandem axles and heavy frames carry skid steers or compact tractors. Boat and personal watercraft trailers are tuned to hulls and bunks. Travel trailers and teardrops meet camping needs, where interior layouts, tanks, and roof seams become inspection priorities. Choose form to match function; versatility is valuable, but the wrong style can add costs you never recoup.

Size and configuration details also influence daily usability. A 6×12 utility trailer is maneuverable in suburbs yet long enough for many mowers or motorcycles; an 8.5×20 enclosed unit swallows larger builds but demands more parking space and a stronger tow vehicle. Axle count affects stability and payload: tandem axles ride smoother and handle flats with less drama, yet they add tire replacement costs. Aluminum frames resist corrosion and weigh less, improving payload and fuel economy; steel is durable and typically more affordable but requires vigilant rust control in snowy climates. Hitch and coupling considerations matter, too. Ball sizes commonly include 2 in and 2-5/16 in; match the coupler and make sure safety chains are properly rated. If your route includes grades or frequent stops, plan on trailer brakes and a compatible brake controller, ensuring control and compliance where required by law.

To narrow options quickly, map needs to specs:

– Payload target: typical DIY chores (1,000–2,500 lb), compact tractors or cars (4,000–7,000 lb), equipment and materials (7,000 lb+).

– Deck style: open for easy loading and tie-downs; enclosed for security and weather protection.

– Axle plan: single for nimble, light-duty trips; tandem for heavier, steadier towing.

– Frame material: steel for value; aluminum for corrosion resistance and weight savings.

When your shortlist aligns tasks, tow rating, and storage realities, you’ll shop with purpose rather than guesswork.

How to Inspect a Used Trailer Like a Pro

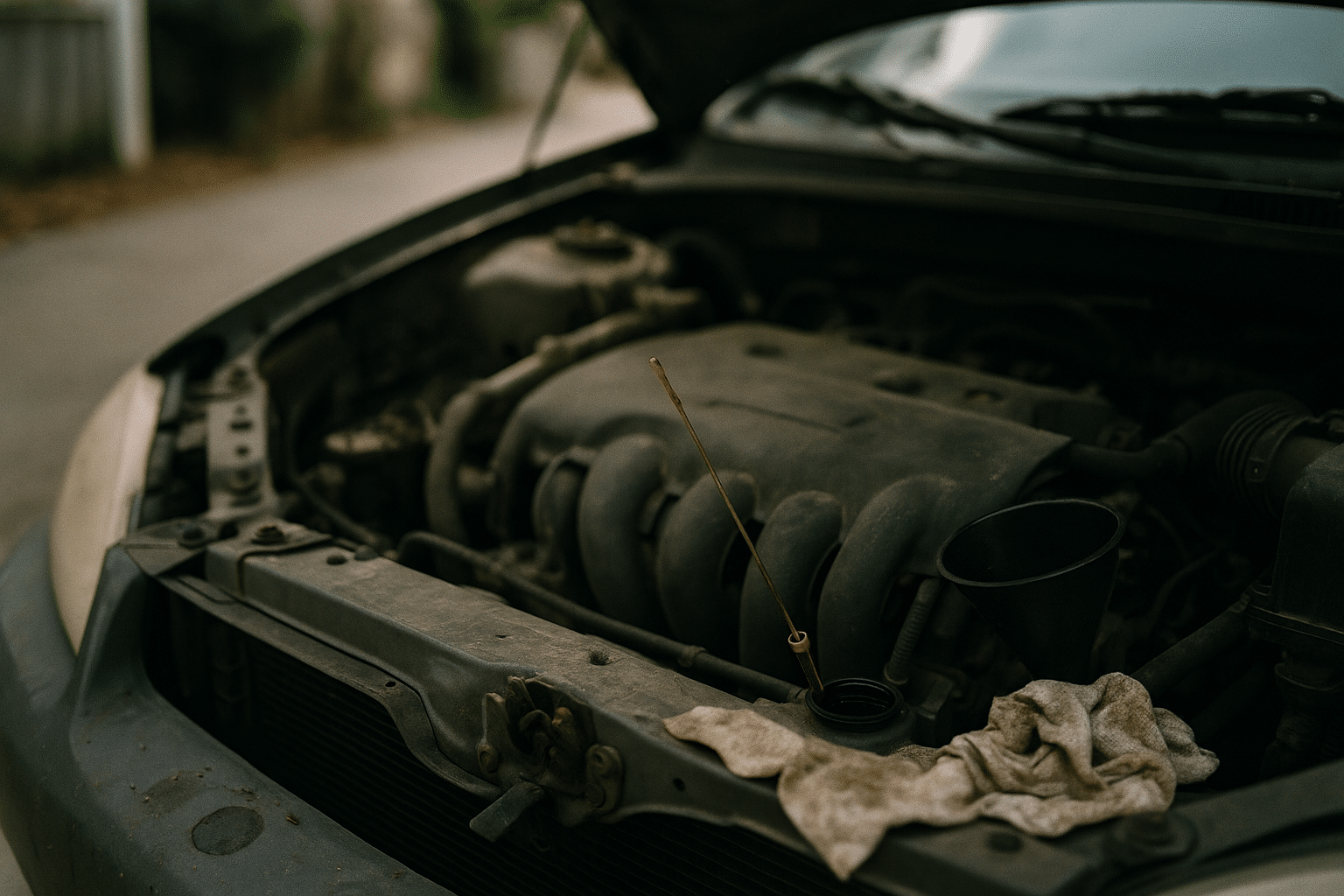

Inspections save time, money, and headaches. Start with the frame—the backbone that carries every load. Look along the main rails and crossmembers for cracks, buckled metal, and weld repairs. Surface rust is common; deep scaling, flaking, or rust-jacking around spring hangers and the tongue is more serious. Sight down the frame for bends. Check the coupler latch for smooth operation and confirm there’s no slop with a matched ball. Spin the jack fully up and down to verify it carries weight and doesn’t bind. Safety chains should have intact hooks and no stretched links. On tilt or dump models, inspect hinge pins and bushings for play; on enclosed trailers, check corners for stress cracks and the roof edge for sealant failure.

Axles and suspension define ride quality and reliability. Leaf springs should sit level with no missing leaves, cracked shackles, or elongated bolt holes. Torsion axles should not sag on one side. Jack the trailer and rock the tires at 12 and 6 o’clock; noticeable movement may indicate loose bearings or worn components. Spin each wheel and listen for grinding. Brake setups vary: electric drum brakes are common, while surge brakes appear on some boat trailers. With electric brakes, examine wiring for chafing and corroded connectors; a test drive with a brake controller should reveal even braking without grabbing. Look at the breakaway switch and battery on braked units—both should be present and functional.

Tires and wheels carry the load, so read them carefully. Trailer-rated tires (often marked ST) should have even tread, no sidewall bulges, and minimal cracking. Check the DOT date code on the sidewall; many owners replace at six to seven years regardless of tread depth due to aging. New tires can cost from modest to several hundred per set depending on size and count, so factor that into price. Verify lug nuts seat correctly and that the wheels match the axle bolt pattern. Spin the hubs after a short drive; excessive heat can hint at bearing or brake issues.

The deck and body reveal how a trailer lived. On wood decks, probe boards for soft spots and inspect for rot around fasteners. On steel or aluminum decks, look for dents that might hide corrosion. For enclosed trailers, check roof seams, front caps, and door frames for water staining; step inside and sniff for musty odors, then shine a light along walls to catch ripples or water trails. Doors should close squarely and locks should work. Electrical lighting must function: running lights, brake lights, and turn signals. A simple checklist helps:

– VIN plate readable and matches paperwork.

– All lights operational with the correct 4-pin or 7-pin connector.

– Floor solid, with no holes near tie-down points.

– Ramps straight and hinges not worn oval.

– Wiring secured along the frame, not dangling.

Finally, verify documents. Title status varies by region, but a clear title (or appropriate registration) protects you from liens and headaches. Match the VIN on the frame to the document, and consider a theft check where available. A short, loaded test—bringing a few hundred pounds of cargo or gear—can expose flex, brake imbalance, or sway you won’t notice empty. If issues surface, price them realistically or walk away; there will always be another trailer.

Pricing, Depreciation, and Smart Negotiation

Understanding value starts with depreciation and condition. Many trailers lose a noticeable portion of their price in the first year or two, then plateau as long as they’re maintained. Heavy-duty or specialty trailers often retain more value because supply is limited. Material matters: aluminum trailers tend to hold value due to corrosion resistance and lower weight, while steel models are widely available and priced accordingly. Regional demand changes the picture, too; snowbelt rust can depress prices, while fast-growing areas with active construction may keep values firm.

Build a quick spreadsheet of comparable listings. Note year, length, width, axle count and rating, brakes, material, deck condition, tire age, and included extras like spare tires, racks, or winches. Then add repair allowances. Example line items:

– Tires: replacing four mid-size ST tires can range widely depending on brand and load rating.

– Bearings/seals/grease: plan a maintenance refresh after purchase.

– Brake service: shoes, magnets, hardware, and labor add up across axles.

– Deck boards: a partial refloor can be straightforward, a full refloor more significant.

– Electrical fixes: lights and a wiring tidy-up are common on older units.

These adjustments transform an asking price into a realistic out-the-door number.

Seasonality influences negotiation. Spring and early summer see higher demand from landscapers, boaters, and DIY movers; sellers may be firmer. Late fall and mid-winter can be friendlier to buyers as projects pause and storage costs loom. Use timing thoughtfully. When you message a seller, be specific: ask for tire date codes, close-ups of the coupler and VIN tag, a shot of the suspension hangers, and a walkaround video with lights on and brakes tested. Specific requests signal you’re serious and discourage vague claims.

Negotiation works best when respectful and data-backed. Share two or three comparable listings that support your offer, account for immediate maintenance you’ll handle, and outline a simple plan: quick inspection, cash or certified funds, and pickup schedule. Keep a firm ceiling; emotion is expensive. Red flags that justify larger discounts or a pass include:

– Title issues or mismatched VINs.

– Uneven brake response on a test drive.

– Severe frame rust near spring hangers or tongue.

– Tires older than six years across the set.

– Wired-in “mystery” lights or add-ons spliced into brake circuits.

Aim for a fair deal, not a miracle, and you’ll land a trailer that earns its keep.

Where to Find Used Trailers and How to Evaluate Listings

Great used trailers change hands in several places, each with trade-offs. Local classifieds and community boards let you inspect quickly and avoid shipping. Online marketplaces expand your reach; you’ll see more inventory and clearer price trends, though distance adds transport and trust hurdles. Dealerships and rental fleets sometimes retire units in batches, offering maintenance records and standardized models at market-aligned prices. Auctions and estate or farm sales can reveal value, but condition can be variable and fees apply; preview days are essential.

Listing quality is your first filter. Photos should cover all sides, the undercarriage, suspension hangers, tongue and coupler, jack, ramps, deck, and a clear shot of the VIN plate. Look for even tire wear, intact safety chains, sealed roof seams on enclosed units, straight fenders, and clean wiring runs. Descriptions that identify GVWR, axle ratings, brake type, wiring connector, and tire date codes suggest a thoughtful owner. Vague posts with two photos and no specs can still hide gems, but you’ll need more diligence.

Before you invest time in a long drive, message the seller with focused questions:

– What is the exact GVWR and axle rating?

– Are brakes functional on all braked axles, and do the lights work?

– What is the DOT date code on each tire?

– Any leaks, frame repairs, or title issues?

– Can you provide a short video showing a cold start to towing (lights, brake check, short roll)?

If answers are evasive or inconsistent, move on. Transparent sellers usually reply with detail and additional photos.

Payment and pickup should be straightforward and safe. Meet in a public place when possible, and examine the VIN and paperwork before exchanging funds. For longer-distance deals, consider a reputable escrow service and a pre-purchase inspection by a local shop. Bring a compatible hitch, a working light adapter, and temporary magnetic tow lights as a backup. Pack a torque wrench, a basic socket set, wheel chocks, a portable inflator, and a jack rated for the trailer’s weight; a roadside stop to tighten lugs after the first few miles is time well spent. If the trailer needs service before a long tow, arrange local storage or transport instead of risking a failed bearing or tire blowout on the highway. A disciplined process turns online browsing into a confident, efficient purchase.

Ownership, Safety, and Final Checklist for Confident Buying

Owning a trailer is simple when you put safety and upkeep on a calendar. Start by learning the data plate: GVWR, axle ratings, and tire load/pressure information. Keep loads within those limits and target a tongue weight around 10–15% of total trailer weight for stable towing. Distribute cargo over the axles, secure with rated tie-downs, and re-check straps at fuel stops. If you add a weight-distribution hitch or sway control for heavier builds, set it up according to the manufacturer’s instructions and verify head height and spring bar tension on level ground.

Maintenance is predictable and budgetable. Repack or replace wheel bearings at intervals recommended by the axle maker or when inspections reveal play or contamination. Inspect brakes and adjust when necessary so braking remains even left to right. Replace tires based on age and condition, not just tread depth; ultraviolet exposure and heat cycles age rubber. Keep a log:

– Pre-trip: lights, tire pressures, lug torque, breakaway battery charge, coupler latch, safety chains.

– Quarterly: brake function test, suspension visual check, wiring insulation.

– Annual: bearing service, full lighting test, deck repair and sealing, rust removal and paint touch-ups.

This rhythm preserves value and keeps you off the shoulder.

Legal and documentation steps protect you as much as the trailer. Register or title promptly according to local requirements, and keep proof of ownership and insurance where applicable. Know brake laws and speed limits for trailers on your common routes; some regions require brakes above specific weight thresholds. If you cross state or provincial lines, verify reciprocity and any special equipment requirements. Retain receipts for tires, brakes, and structural repairs; buyers appreciate records, and they can support your asking price when you eventually sell.

Before you hand over money, run this final buyer’s checklist:

– The trailer’s specs match your tow vehicle’s ratings.

– Frame is straight; no critical rust around hangers, tongue, or coupler.

– Bearings quiet, wheels true, tires within age and condition limits.

– Brakes engage smoothly; breakaway system intact.

– Lights and wiring clean; VIN plate legible and matches paperwork.

– Title clear; bill of sale prepared with VIN, price, and date.

When these boxes are ticked, you’re not gambling—you’re investing in a tool that pays back with every safe, on-time haul. Treat the search as a short course in practical mechanics, negotiate with the calm confidence of someone who can walk away, and you’ll drive home with a trailer that’s ready to work as hard as you do.